TREADMILL

WOODWAY 4FRONT – ELG – DESMO

MAINTENANCE AND TROUBLESHOOTING

Cleaning and Inspection

CAUTION: Turn off treadmill and disconnect power cord before cleaning.

Weekly:

# Clean handrail, front display panel, cosmetic

covers & running belt.

Inspect

power cord. (make sure all prongs are present & cord is not frayed or cut)

# Check overall condition of the treadmill.

Replace Necessary part.

# Move, and vacuum underneath the treadmill.

# Check magnet assembly. (magnet, lanyard &

clip)

# Ensure the red emergency stop button is

functioning correctly. (*ELG treadmill)

Every Six (6) Months:

Every Six (6) Months:

# Vacuum inside the treadmill (unplug and remove

cosmetic covers)

# Inspect all nuts and bolts. Tighten or replace

as needed.

# Clean running surface with a diluted cleaner

such as 409 or Fantastic. Ratio 50/50.

# Check drive belt – replace if teeth are

missing or shredded.

# Inspect running belt (tighten all slat

screws & check belt tension)

# Inspect the set screws on shaft bearings

# Check calibrations

Yearly:

Yearly:

# Grease bearings on front idler shaft &

rear drive shaft.

# Grease rear drive shaft pulleys

# Grease elevation racks & chains

# Remove 2 belt slats to clean bearing rails

& the inside of the running belt

Seasonally:

In autumn & winter remember that the dry

climate in many regions of the country will cause a greater static discharge to

occur when the treadmill is used. Be sure to spray the running surface with a

staticide spray regularly to prevent static shock to the treadmill users and to

prevent interference with the treadmill’s electronic systems.

Lubrication

Lubrication: Black or White lithium grease is

recommended

Bearings

Bearings

Almost all of the bearings used in the treadmill are

pre-lubricated and do not need to be greased. On a yearly basis, the four (4)

bearings located at the front and rear shaft will need to be lubricated. One pump

of grease can be inserted into the zirk fittings on the bearings. A grease gun

with a flex bit will be needed for this portion. The bolts that secure the

bearings to the frame need to be tightened if necessary. The set screws on the

bearing collars need to be tightened and should have red loctite on them to

ensure they stay tight. All set screw torque settings need to be at 78 in lbs.

The ELG torque setting for the set screws needs to be 273 in lbs.

Running Belt

The teeth on the bottom of the running belt are

pre-lubricated to aid in reducing noise. There is no need to lubricate the

teeth. If running belt is rubbing against the side of the drive pulleys, then a

small amount of grease (i.e. Molykote or equal) on the edges of the belt slats

will help reduce noise. Apply grease to the teeth on the back drive shaft to

help the belt stay aligned properly.

Running Shaft Assembly

The rear drive shaft pulleys should be greased

once a year. A bead of grease can be applied to each set of teeth. Use

sparingly. Inspect the teeth for any damage. If the teeth are damaged, the

drive shaft assembly will need to be replaced as the running belt will not stay

aligned or tensioned correctly.

Drive Belt

Drive Belt

As in the case of the running belt, the

application of grease on the edge of the drive belt is only needed to reduce

belt squeak and should be used sparingly. The drive belt is a cogged tooth belt

and may stretch; tighten if necessary. Inspect drive belt to make sure all

teeth are present. Replace drive belt if teeth are missing or if belt is

shredding.

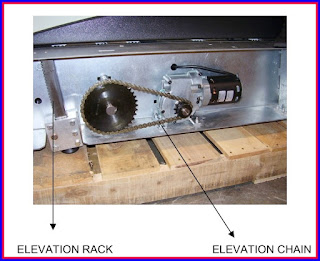

Incline System

The incline systems on WOODWAY treadmills are

greased at the factory. If utilized for many hours or in a very dusty

environment, system will need to be checked. If needed, a small amount of

grease can be applied to the elevation racks and also applied to the elevation

chains. Do not use too much grease. Make sure the hardware that holds the

elevation blocks to the racks is secure and tight.

Note: Use a minimal amount of

lubrication to prevent excess dirt and debris from sticking to the machine after cleaning.

Adjustments and Calibration

Incline System

Adjustments and Calibration

Incline System

The Rack and Pinion style incline system is used

in WOODWAY treadmills. The 15% & 25% incline systems use similar components

and only differ in rack travel.

Bearing Rails

Bearing Rails

Remove 2 running belt slats to access the

bearing rail assemblies. Clean the bearing rails and replace any bearing that

is causing a noise issue or that does not spin freely.

Running Belt

Running Belt

The running belt should not require adjustment.

However, if the running belt or associated parts have been changed, then belt

tension should be checked and set at 8.5 for Mercury and Desmo models and 8.25

for Path and Wide Path treadmills.

Handrails

Handrails

Inspect/tighten all hardware. Replace any hardware that is

stripped or missing. Inspect the handrail clamps for cracking.

Treadmill Mounting Feet

Treadmill Mounting Feet

TOOLS NEEDED: 2 FT LEVEL, ¾ INCH WRENCH If

treadmill wobbles or seems unstable, mounting feet must be checked. Using the

level, check both ends of the treadmill. Loosen the tensioning nut and turn the

foot until it is at the correct level. Tighten the tensioning nut.

ELG with Gantry

Inspect/tighten all hardware on gantry. Replace

any hardware that is stripped or missing. Inspect safety harness system.

Note: When moving the treadmill the frame may flex. If treadmill seems unstable, push

handrail to one side or the other. If treadmill is still unstable check mounting feet for

adjustment.

Note: When moving the treadmill the frame may flex. If treadmill seems unstable, push

handrail to one side or the other. If treadmill is still unstable check mounting feet for

adjustment.

Troubleshooting

1. No Display:

1. No Display:

If the treadmill’s display does not light up

when powered on, check the following items:

# Input power fuse – replace if blown

# Power coming out of wall outlet

# Check power with another piece of equipment

(radio, fan, etc.). Check main fuse or circuit breaker, move to another outlet.

# Is the treadmill plugged in?

# Is the safety magnet installed or positioned

correctly? Try to reposition. Check all connectors at circuit boards.

2. Belt Movement

2. Belt Movement

# Is the safety magnet on?

# Is the display working properly?

# If the display works, and/or the incline

works, unplug the treadmill and wait at least 60 seconds before plugging it

back in.

BELT TIGHT/HARD TO PUSH

First, determine if display board is illuminated

and/or if the incline system is working. This information will help our service

technician in advising you where the source of the problem may be.

BELT BINDING

Check for

obstructions and remove if possible.

3. Incline Does Not Work

# Check for any noises from the incline motor

(brake sticking/motor stalled)

# Check if incline limit switches are tripped.

# Check for broken chain, or if chain has jumped

off of any sprockets.

# Check if the potentiometer is adjusted

correctly.

4. Erratic or Blinking Display

4. Erratic or Blinking Display

# Probable causes: Low line voltage; too much

load on the same line.

# Make sure treadmill is on a dedicated

electrical circuit.

3 Display power supply on Interface board is

defective.

5. Squeaking Sounds:

5. Squeaking Sounds:

Possible causes:

# Noisy bearing . Try greasing or replacing

the bearing.

# Drive

belt rubbing against the drive pulley, try greasing the edge of the drive belt

with a little all-purpose grease.

# Running belt rubbing against drive pulleys,

try lightly greasing the teeth on the drive shaft, and let the treadmill run at

a slow speed for a couple of minutes to spread grease evenly. (NOTE: Too much

grease will make a mess and will accumulate dust).

# Check for a defective guide roller or Z roller bearing on the bearing rail, replace if defective.

# Check for a defective guide roller or Z roller bearing on the bearing rail, replace if defective.